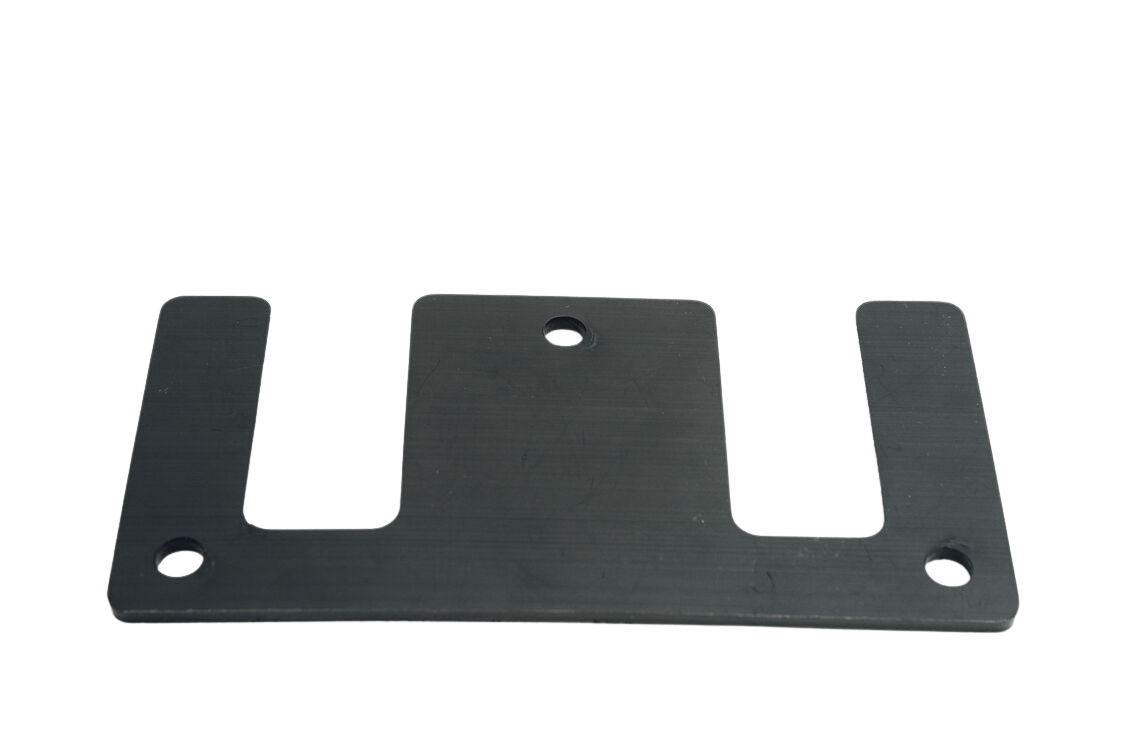

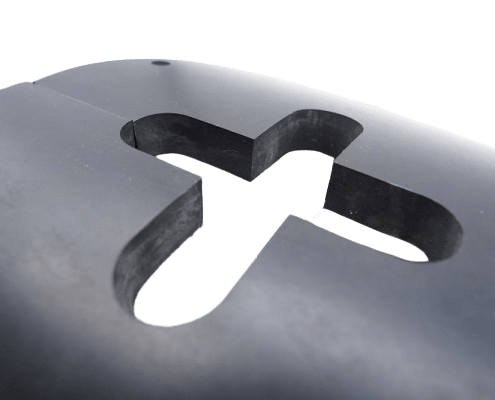

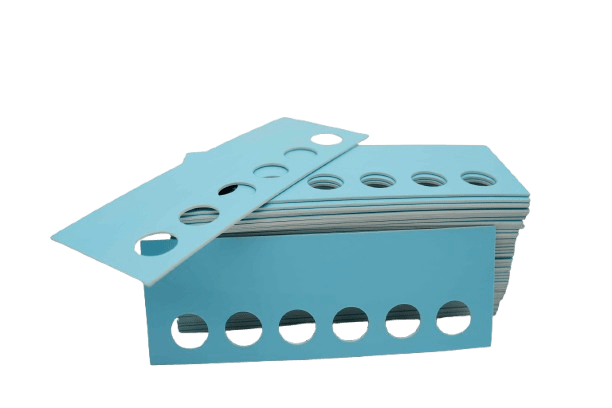

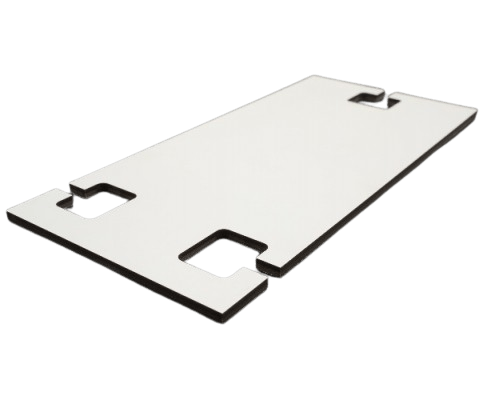

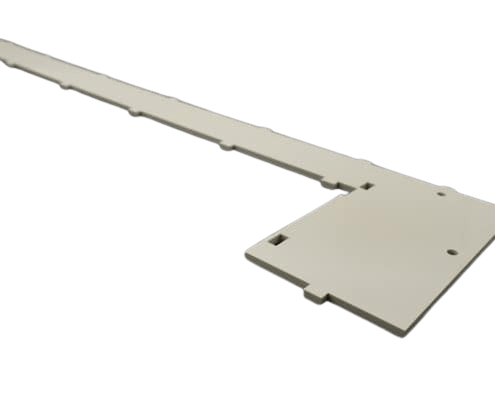

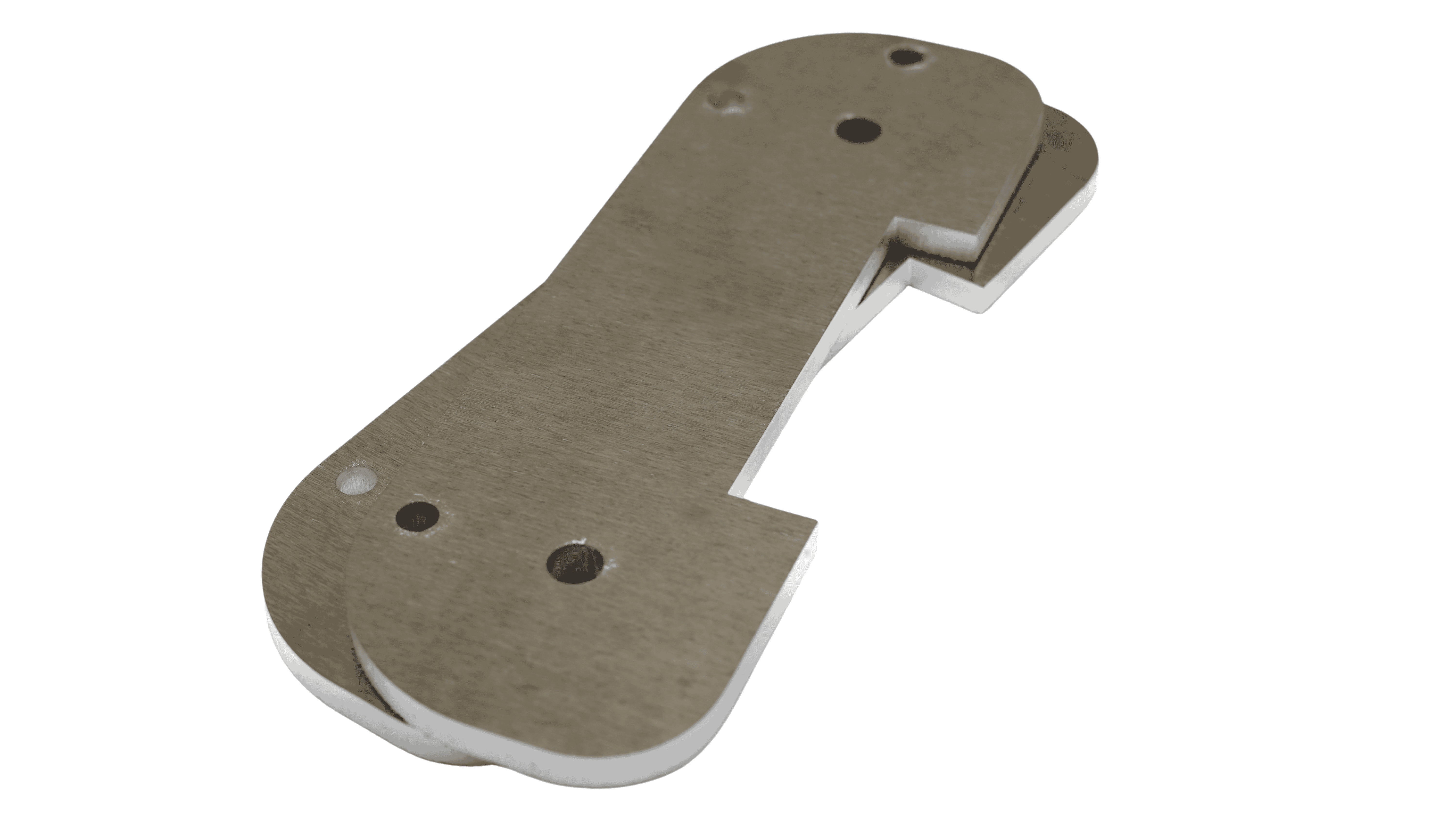

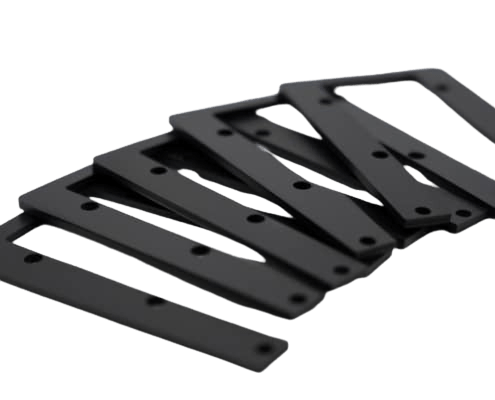

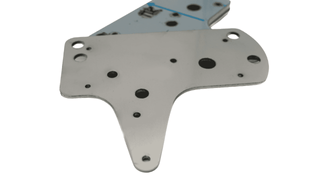

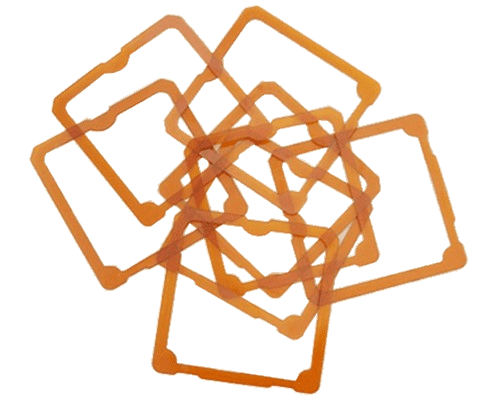

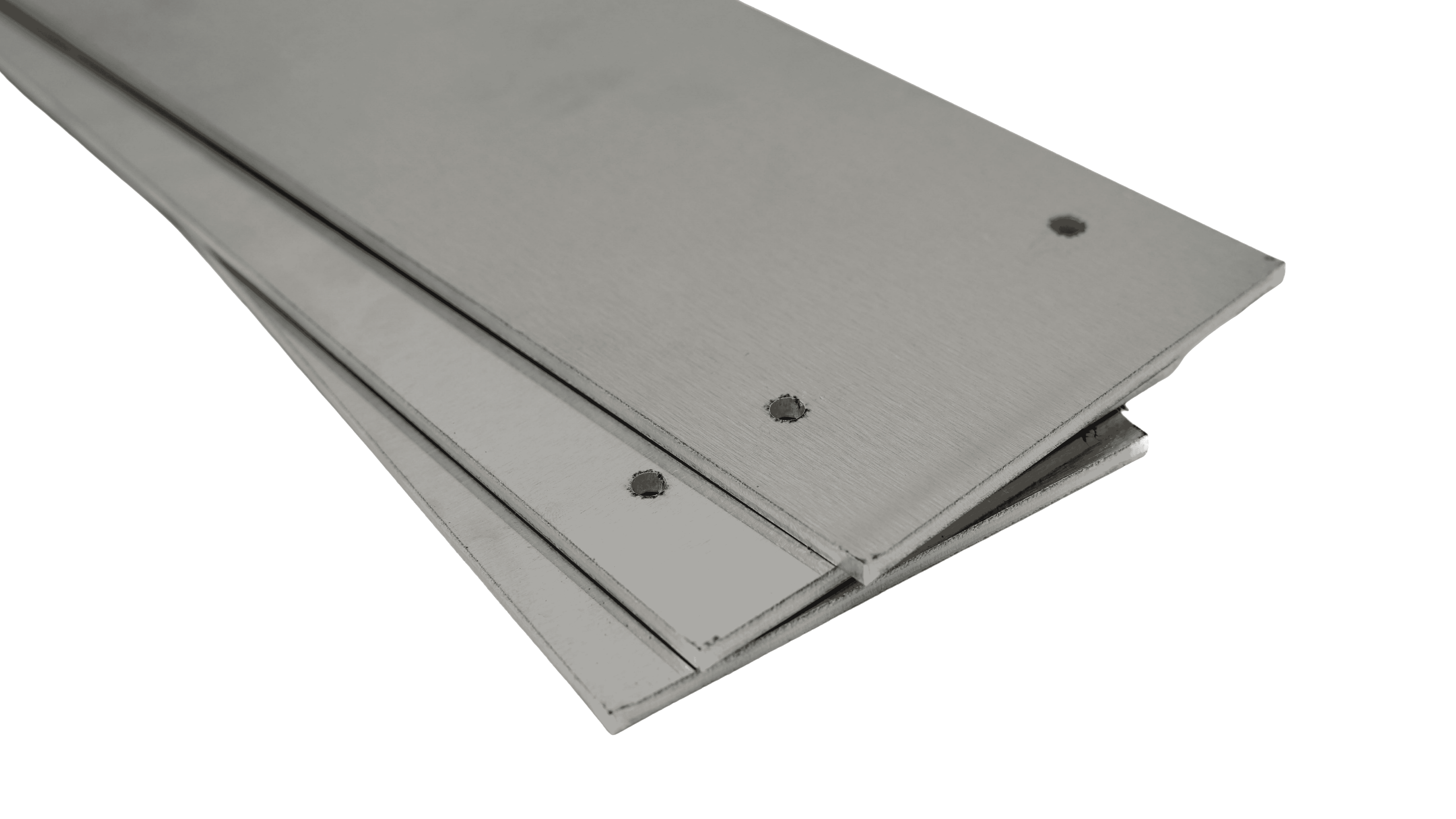

PET-P (Polyethylene Terephthalate)

Plastic

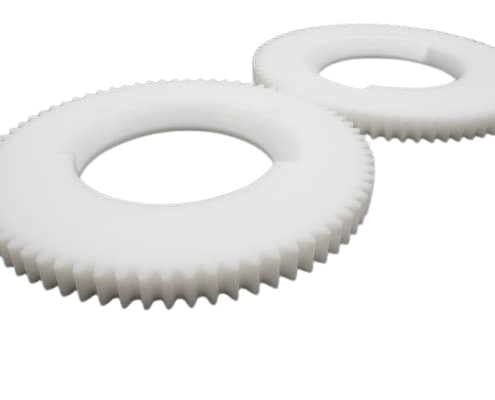

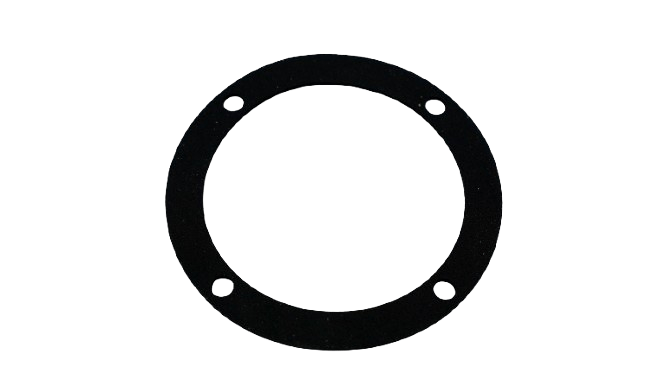

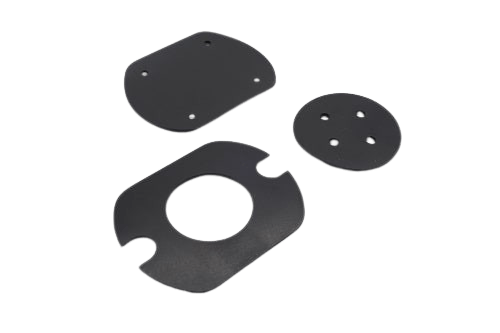

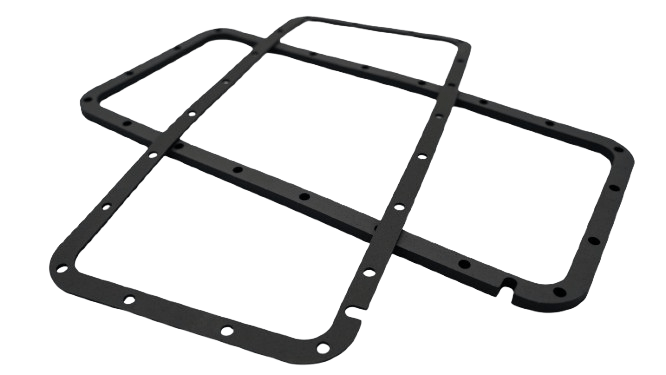

PET-P, also known as hard PET, is a strong, dimensionally stable engineering plastic with excellent sliding and wear properties. The material is particularly suitable for precision components that deform very little, even under prolonged load. PET-P is wear-resistant, moisture-resistant, and easily machinable, making it widely used in technical applications where dimensional accuracy is crucial.

Well-known trade names for PET-P include Ertalyte®, Arnite®, Sustodur®, and Tecapet®. These high-quality PET plastics are often used in machine building and the food industry.

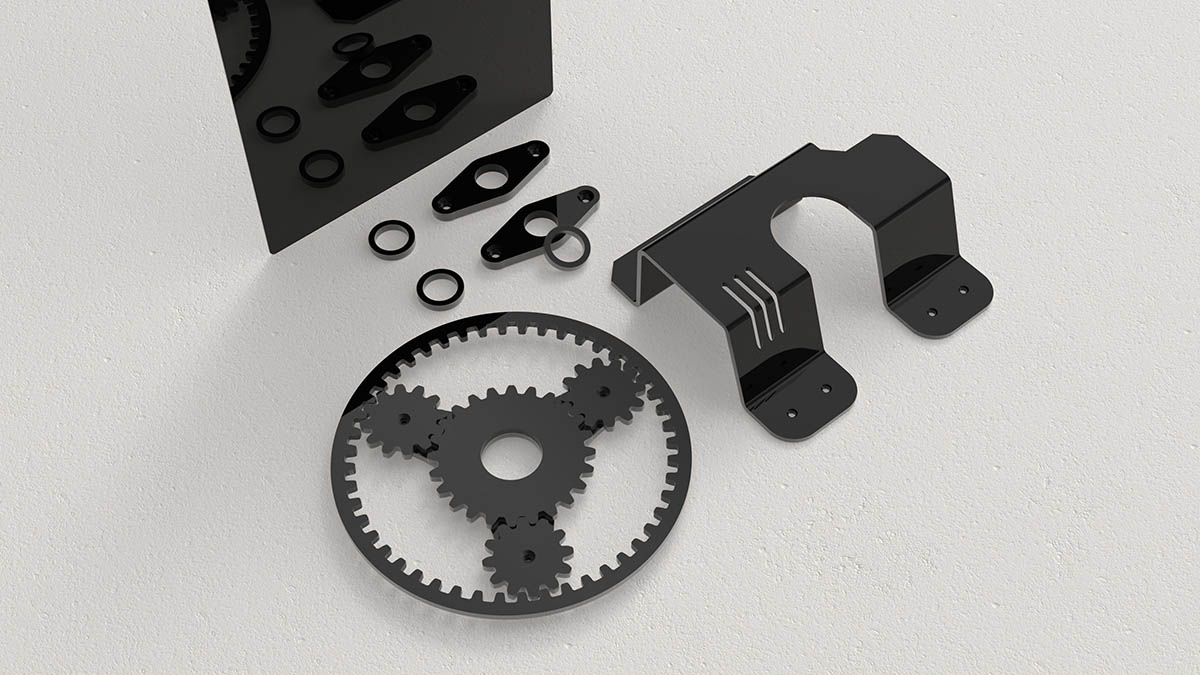

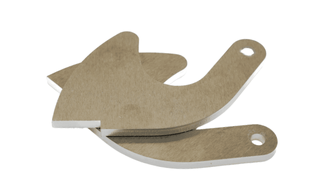

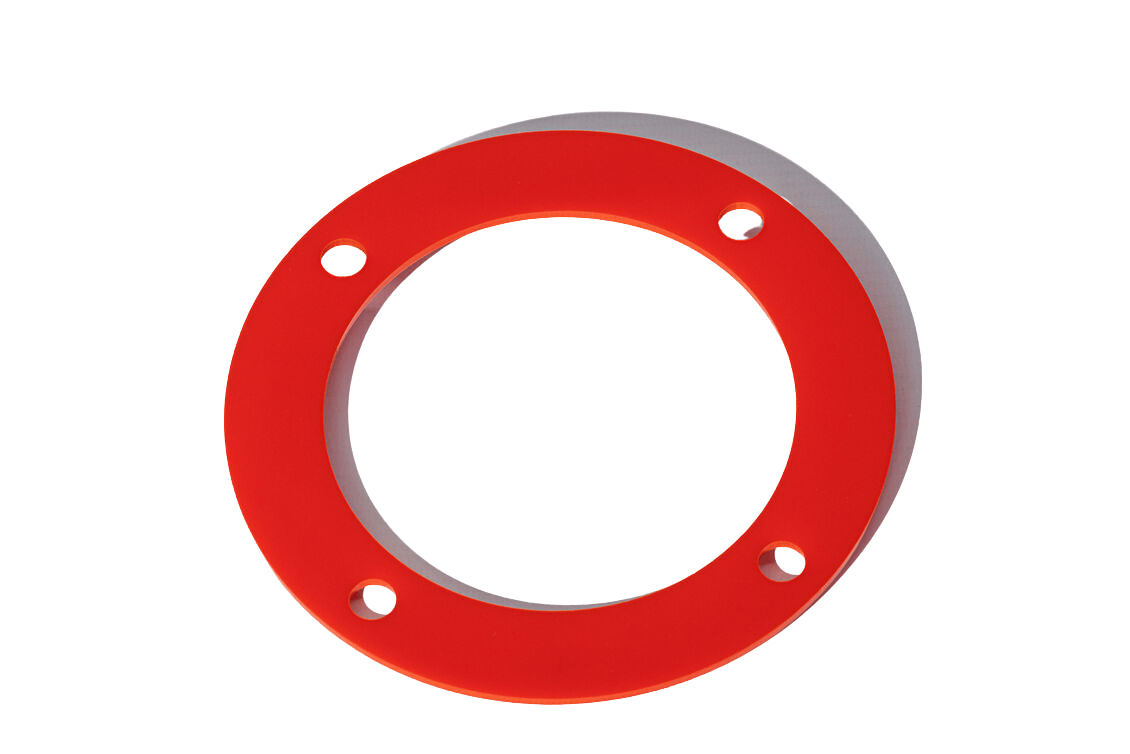

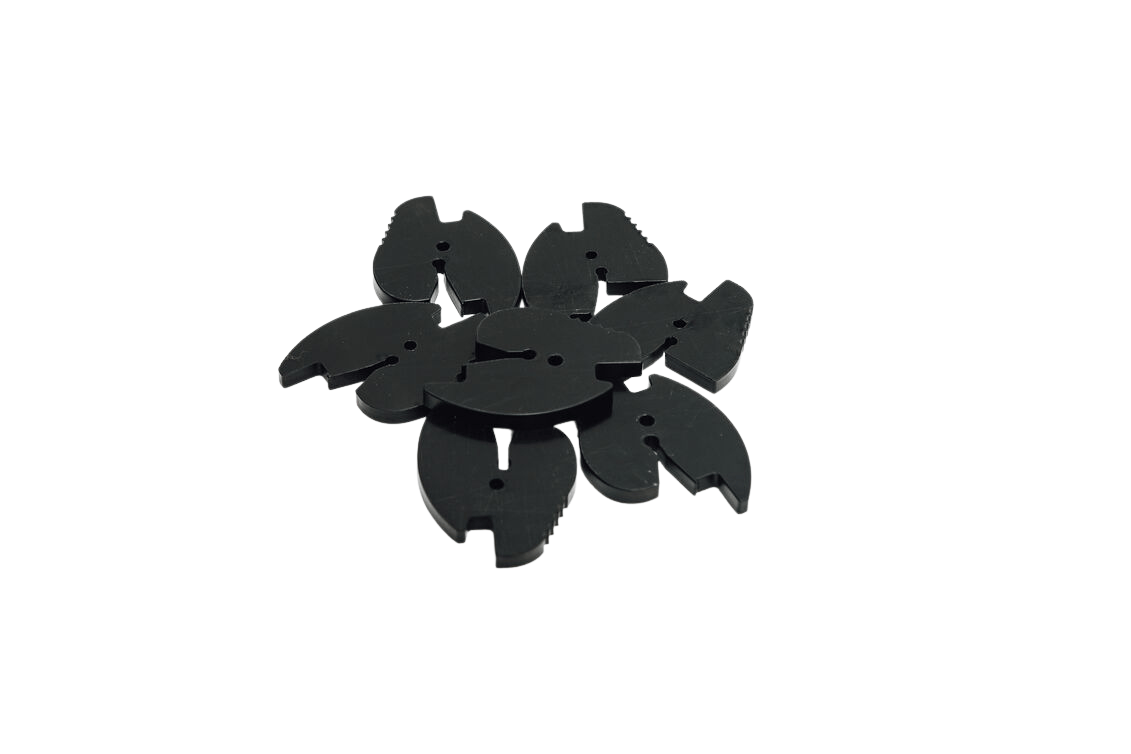

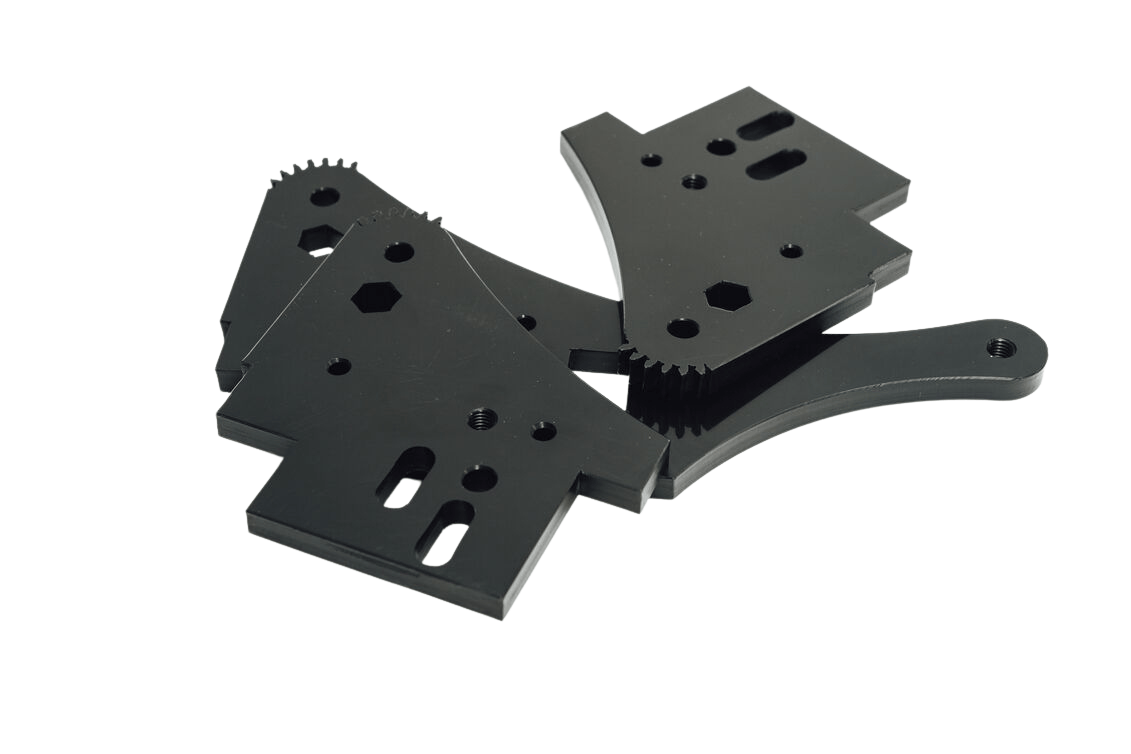

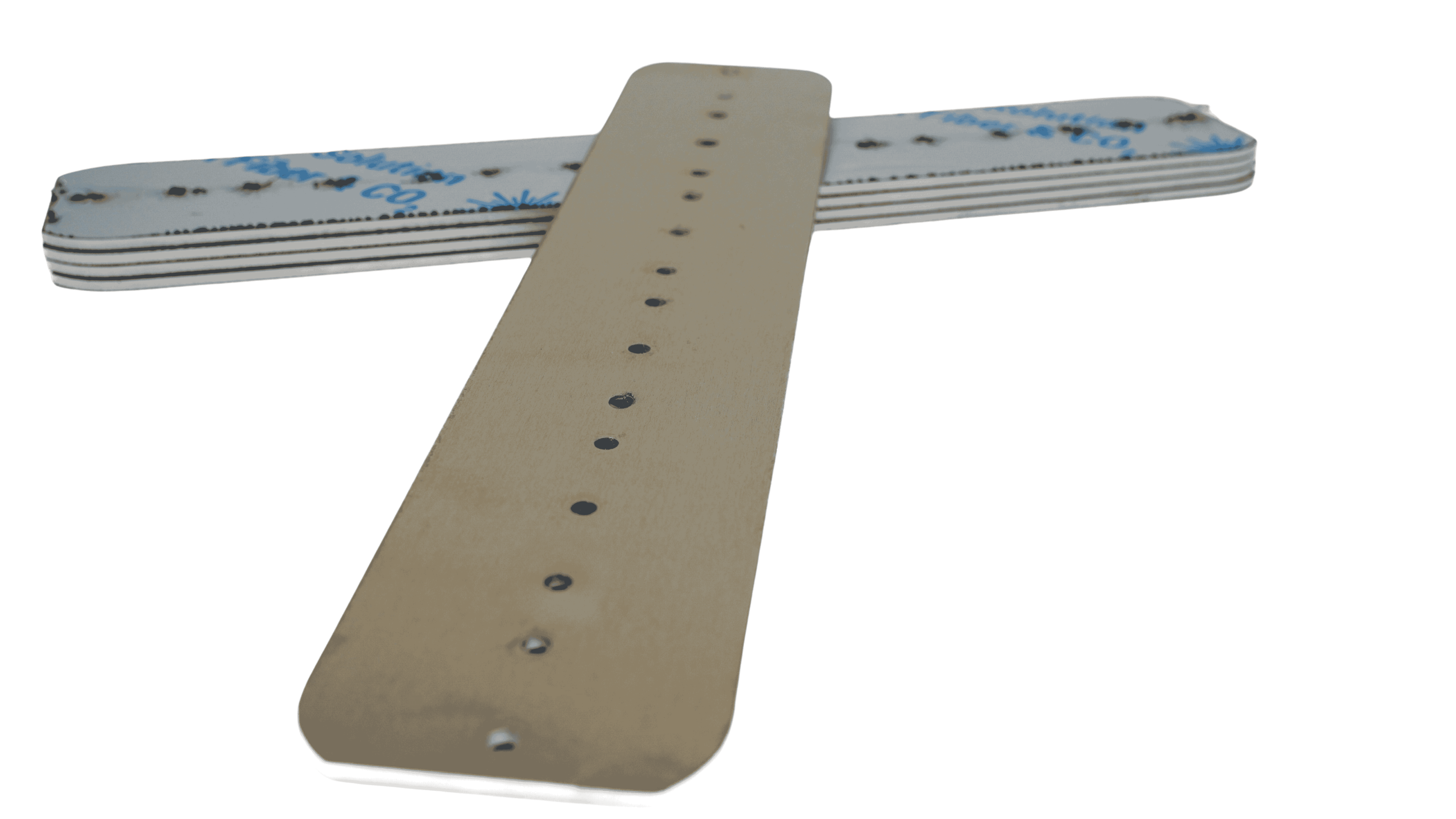

- Laser cutting

- Milling